Product Overview

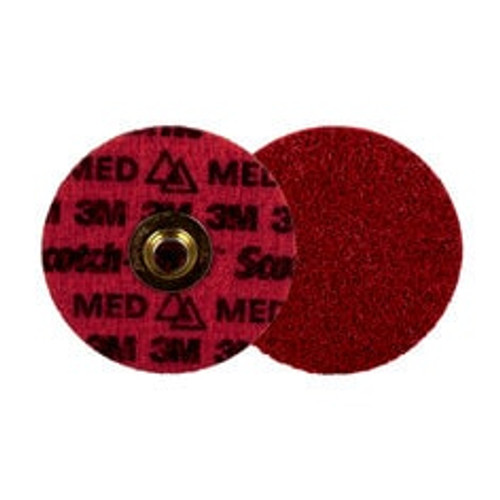

3M Sales UPC: 00638060893722; 3M 5-Digit Part Number: 89372; 3M Previous Stock Number: 61500408481; 3M Consumer UPC: No Data; 3M Inner UPC: No Data; 3M Shipper UPC: 50638060893727; Ship Container Length: 31.750 (Centimeter); Ship Container Height: 17.780 (Centimeter); Ship Container Width: 31.750 (Centimeter); Ship Container Volume: 17923.350 (Cubic centimeter); Ship Container Weight: 1457.845 (Gram); Shelf Life: 1825 Days; Country of Origin: USA; ECCN Number: EAR99; Harmonizing Code: 6805301000; Transport Protective Service: PROTECTIVE SERVICE NOT REQUIRED; NMFC Item: 049160; NMFC Sub: 00; NMFC Class: 000.0; US DOT, 49 CFR Ground: NOT REGULATED; US DOT, 49 CFR Vessel: NOT REGULATED; International Air Transport Association (IATA): NOT REGULATED; International Maritime Organization (IMO): NOT REGULATED. Product Information: Scotch-Brite™ Precision Surface Conditioning TN Quick Change Discs set a new standard in surface conditioning performance. These reformulated general-purpose discs feature 3M Precision-Shaped Grain technology incorporated into the nonwoven web, bringing a new level of productivity and abrasive life to the Scotch-Brite™ lineup.. Redesigned with you in mind.

Meet the next advancement in surface conditioning technologies: Scotch-Brite™ Precision Surface Conditioning TN Quick Change Discs. This new addition to the Scotch-Brite™ lineup promises the consistency you’ve come to expect with increased cutting speed and longer abrasive life. By combining two flagship 3M technologies — nonwoven fibre and ceramic 3M Precision-Shaped Grain — you can get the ideal finish, faster. To help you be even more efficient, these discs come in brighter, more vivid colors to make identification easier. Plus, the grade range has been expanded to include Fine and Extra Coarse offerings, providing an even larger range of solutions for your abrasive needs.

Ready to improve your process.

These premium general-purpose discs are designed to streamline surface conditioning processes including cleaning, blending, deburring and finishing. Typical substrates include aluminum and soft metals, carbon steel and stainless steel, with applications ranging from coating and corrosion removal to refining and post-cast processing.

Applications

Coating removal

Corrosion removal

Refining coated abrasive scratches

Refining machine marks

Post-cast processing

Burr removal

Removing micro-burrs